1. Introduction: The Rise of NAD+ in Modern Health Science

If there’s one molecule that’s quietly rewriting the story of modern health and longevity, it’s Nicotinamide Adenine Dinucleotide, or NAD+ for short. You’ve probably heard about it being the “fuel for life,” the molecule that keeps our cells running, repairing, and regenerating. But behind every NAD+ supplement on the market — whether it’s in capsule, powder, or intravenous form — lies a critical foundation: the raw material manufacturer.

Think of NAD+ like electricity for the human body. It powers every biological “appliance,” from DNA repair to cellular energy metabolism. Without NAD+, our cells lose their spark — and eventually, so do we. That’s why scientists and health innovators around the world are obsessed with finding ways to restore and boost NAD+ levels, especially as we age.

Why NAD+ Matters in the Modern World

In today’s fast-paced, high-stress environment, our bodies are under constant metabolic and oxidative pressure. NAD+ levels naturally decline by up to 50% by middle age, and that depletion accelerates under stress, poor sleep, and unhealthy lifestyles. When NAD+ drops, energy levels fall, DNA repair slows, and aging speeds up.

That’s where the global NAD+ supplement industry enters the picture — a market that’s growing at lightning speed. From anti-aging supplements and sports performance enhancers to cellular repair formulations in pharmaceuticals and skincare, NAD+ has become the golden molecule everyone wants a piece of.

But here’s the thing most people overlook: the quality of NAD+ products starts with the raw material. Just as a luxury car depends on precision-engineered parts, an effective NAD+ supplement depends on pure, bioavailable, and safe raw material.

That’s why NAD+ raw material manufacturers are in the spotlight. They’re the unsung heroes ensuring every gram of NAD+, NMN (Nicotinamide Mononucleotide), or NR (Nicotinamide Riboside) meets the highest standards of purity, potency, and consistency.

The Global Demand Surge for NAD+ Raw Materials

In just the past five years, the NAD+ industry has seen explosive growth. According to market data, global demand for NAD+ and its precursors has grown by over 25% annually, driven by consumer awareness and new clinical evidence linking NAD+ to longevity, metabolism, and brain health.

Countries like the United States, Japan, South Korea, and China are leading the boom — not just in supplement production, but in biotech R&D and raw material innovation. The result? A fiercely competitive marketplace where manufacturers must balance innovation, purity, and scalability to meet the soaring demand.

And that’s where choosing the right NAD+ raw material manufacturer becomes more than just a supply chain decision — it’s a strategic investment in quality, brand trust, and scientific credibility.

2. Understanding NAD+: The Molecule Behind Cellular Energy

Before diving deeper into the manufacturing process, it’s crucial to truly understand what NAD+ is — and why it’s so fundamental to life itself.

What Exactly Is NAD+?

NAD+ stands for Nicotinamide Adenine Dinucleotide, a coenzyme found in every living cell. Imagine it as a molecular “currency” that powers countless biological transactions. NAD+ helps convert nutrients into energy, assists in DNA repair, supports immune function, and even influences circadian rhythms — the internal clock that tells your body when to sleep, eat, and repair.

In simpler terms: without NAD+, your body’s energy system grinds to a halt.

The Biological Role of NAD+

NAD+ plays a starring role inside the mitochondria, the powerhouses of your cells. It acts as a carrier molecule that shuttles electrons during the process of energy production — a bit like a battery constantly charging and discharging to keep the lights on.

But NAD+ isn’t just about energy. It also activates sirtuins, a family of proteins known for regulating metabolism, DNA stability, and lifespan. These “longevity genes” depend directly on NAD+ to function. So when NAD+ levels drop, sirtuin activity declines — leading to faster aging, metabolic dysfunction, and decreased resilience to stress.

Why NAD+ Levels Decline with Age and Stress

Just like a smartphone battery that holds less charge over time, our NAD+ reserves diminish as we age. Environmental toxins, UV exposure, poor diet, and chronic stress all drain the body’s NAD+ supply.

By age 50, most people have less than half the NAD+ they had in their twenties. The result? Slower metabolism, cognitive fatigue, weaker immunity, and visible signs of aging like wrinkles and muscle loss.

This decline is precisely why NAD+ precursors like NMN, NR, and NAM (Nicotinamide) have gained so much attention. These compounds act as “building blocks” that the body can convert into NAD+, helping restore optimal cellular function.

The Rise of NAD+ Precursors in the Market

As direct NAD+ supplementation faces challenges (mainly due to poor bioavailability when taken orally), companies are shifting focus toward NAD+ precursors. These are molecules that the body naturally transforms into NAD+ through enzymatic reactions.

Here’s a quick overview:

| Precursor Type | Full Name | Conversion Efficiency | Market Use | Advantages | Challenges |

| NMN | Nicotinamide Mononucleotide | High | Supplements, skincare | Strongest scientific backing; better stability | Costlier than NR |

| NR | Nicotinamide Riboside | Moderate | Capsules, energy drinks | Well-researched; easily absorbed | Slightly less efficient |

| NAM | Nicotinamide | Low–Moderate | Multi-vitamin blends | Cheaper, widely available | May inhibit sirtuins at high doses |

As the table shows, NMN currently leads the race, particularly in the premium supplement market, where consumers are willing to pay more for bioavailability and research-backed results. Compared to synthetic NAD+, bio-fermented NMN is seen as a better, cleaner, and safer option — aligning with the industry’s shift toward green chemistry and sustainable sourcing.

Connecting Biology with Business: Why NAD+ Manufacturing Quality Matters

Now, imagine you’re a supplement brand looking to launch a new line of NAD+ or NMN products. You’ve got the marketing, the branding, the distribution channels — but if your raw materials aren’t up to par, none of that matters.

Low-quality NAD+ raw materials can lead to:

Reduced bioavailability, meaning your customers feel no effect.

Impurities or contaminants, risking safety and recalls.

Inconsistent batches, which can erode brand trust.

In contrast, a high-quality NAD+ raw material manufacturer ensures every kilogram of powder meets pharmaceutical-grade standards. They follow strict GMP (Good Manufacturing Practice) protocols, use advanced purification techniques like HPLC (High-Performance Liquid Chromatography), and maintain full traceability from fermentation tank to final drum.

In other words — great NAD+ products start with great science.

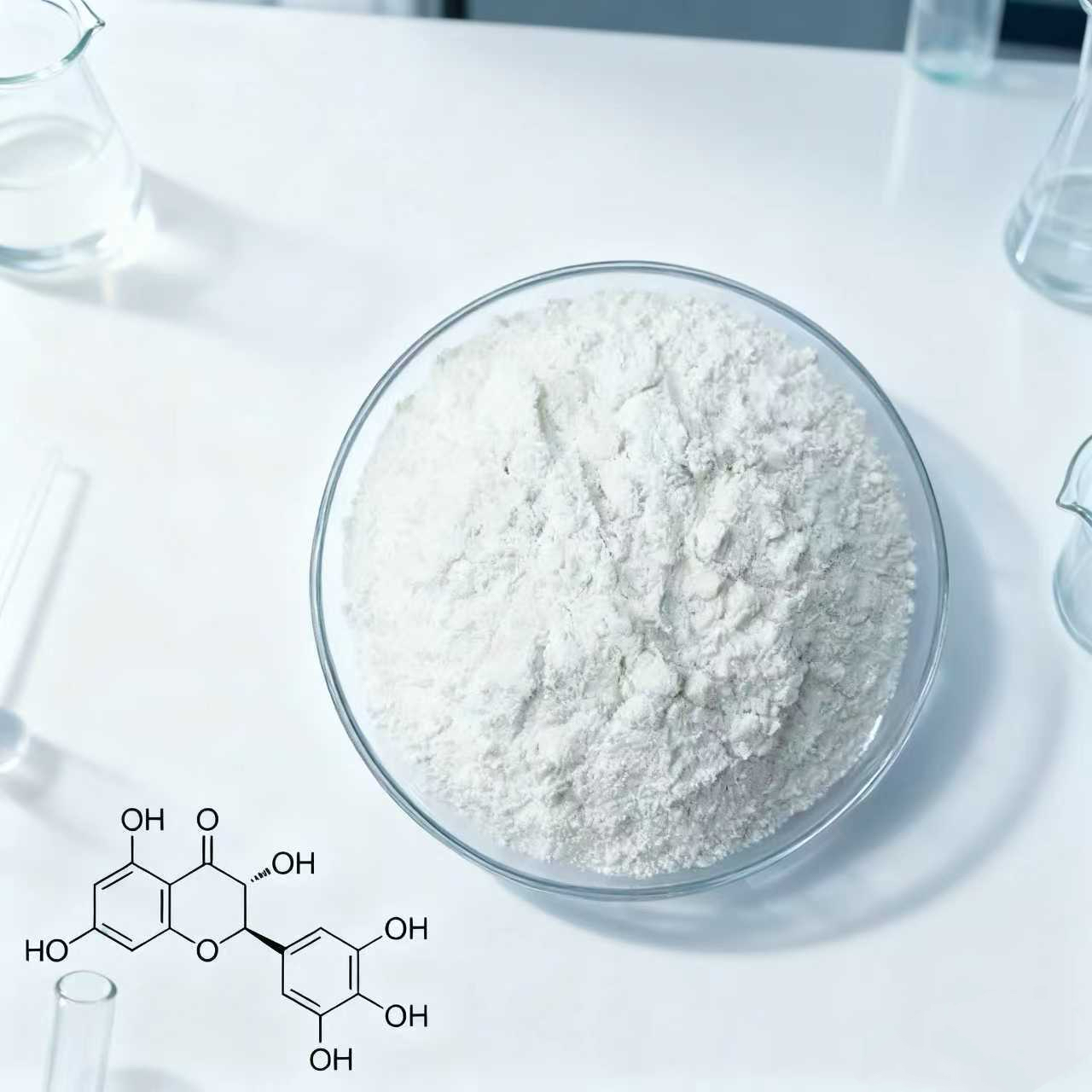

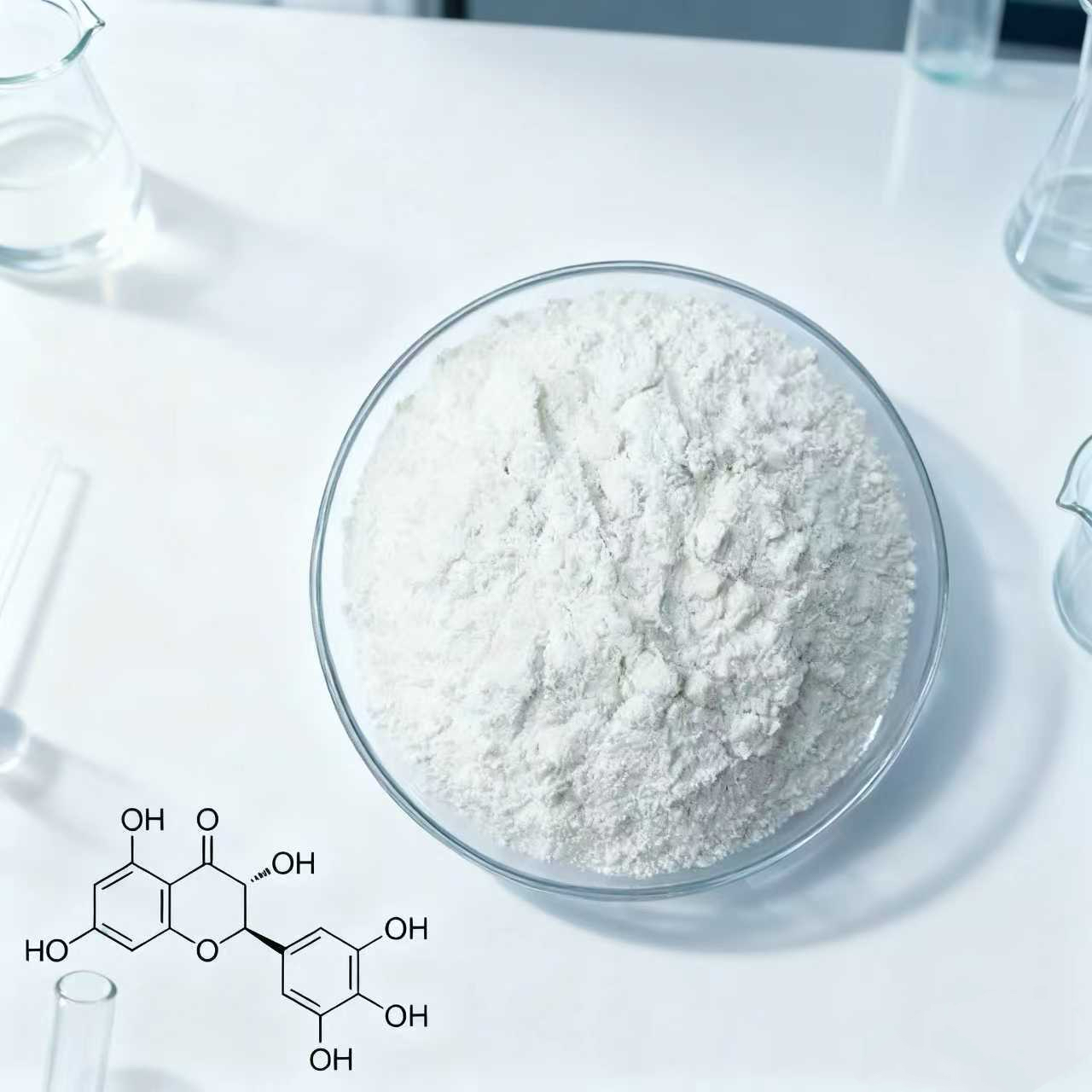

3. From Lab to Life: How NAD+ Raw Materials Are Manufactured

If you’ve ever wondered how NAD+ or its precursors make the leap from a complex biochemical concept to a fine, pure white powder in a supplement capsule — welcome behind the curtain. Manufacturing NAD+ raw materials isn’t just chemistry; it’s precision biotech engineering combined with strict regulatory control.

Let’s unpack the process from start to finish.

Step 1: Biosynthesis — The Art of Molecular Creation

The first stage in NAD+ raw material production is biosynthesis, which can occur via chemical synthesis or biological fermentation.

Most high-end manufacturers today are shifting toward enzymatic or microbial fermentation methods. Why? Because they’re cleaner, greener, and more efficient compared to older chemical synthesis techniques that rely on harsh solvents.

Chemical Synthesis vs. Fermentation-Based Production

| Aspect | Chemical Synthesis | Bio-Fermentation / Enzymatic Synthesis |

| Purity | Moderate | High (fewer byproducts) |

| Environmental Impact | Higher (uses solvents, generates waste) | Lower (eco-friendly, biodegradable media) |

| Cost | Initially cheaper but less scalable | Slightly more expensive but highly scalable |

| Consistency | Variable batch results | Stable, consistent yields |

| Market Preference | Declining | Rapidly growing |

Fermentation-based manufacturing uses engineered bacteria or yeast strains to produce NAD+ precursors like NMN and NR naturally. These microbes are cultured under carefully controlled conditions — temperature, pH, nutrient levels — to maximize yield and minimize impurities.

This process mimics what happens inside the human body’s cells, which is why it’s considered more natural and bio-identical. The final result? A cleaner, safer, and better-performing raw material that’s ideal for nutritional supplements and pharmaceuticals.

Step 2: Purification — The Journey to 99.9% Purity

Once the NAD+ precursor is synthesized, it goes through multi-step purification to remove any residual biomass, solvents, or unwanted molecules. This is where advanced technologies like:

HPLC (High-Performance Liquid Chromatography)

Ion-exchange chromatography

Membrane filtration

Crystallization purification

come into play.

Each batch undergoes rigorous filtering and testing to ensure purity levels above 99%. A high-quality NAD+ raw material manufacturer doesn’t just stop there — they often run triple-layer verification, confirming composition with mass spectrometry (MS) and nuclear magnetic resonance (NMR).

Think of it as refining gold. You start with raw ore and end with a flawless, gleaming metal — only in this case, it’s the molecular gold that powers cellular vitality.

Step 3: Drying and Milling — Turning Molecules into Market-Ready Powder

After purification, the next challenge is transforming the pure compound into a stable, free-flowing powder. Manufacturers use advanced drying technologies such as freeze-drying (lyophilization) or spray drying, depending on the product’s intended use.

Freeze-drying preserves molecular integrity and bioactivity, ideal for high-end NMN and NAD+ products.

Spray drying is faster and more cost-efficient for large-scale production.

The resulting powder is then milled, sieved, and standardized for particle size — ensuring consistent performance across batches. This step might sound trivial, but for supplement formulators, it’s the difference between a product that blends perfectly and one that clumps or degrades quickly.

Step 4: Quality Control and GMP Compliance

At this stage, the focus shifts from chemistry to quality assurance. A trusted NAD+ raw material manufacturer must meet Good Manufacturing Practice (GMP) standards and maintain compliance with ISO, FDA, and other international certifications.

Every batch is subjected to:

Purity and assay tests (e.g., HPLC, UV spectroscopy)

Microbial contamination testing

Heavy metal and solvent residue analysis

Moisture content and stability testing

These measures ensure that the NAD+ raw material delivered to supplement brands is safe, potent, and consistent.

A good manufacturer doesn’t just provide a Certificate of Analysis (CoA); they offer full traceability from raw inputs to finished product. That transparency builds trust and ensures that every supplement brand can prove their product’s authenticity.

Step 5: Packaging and Storage — Protecting Molecular Integrity

NAD+ and its precursors are sensitive to heat, light, and moisture. That’s why reputable manufacturers use nitrogen-sealed aluminum foil bags or vacuum packaging inside controlled humidity environments.

Temperature-controlled warehouses and cold chain logistics are often used for shipping to preserve potency — especially for high-value NMN and NAD+ powders that degrade faster than typical vitamins.

In short: manufacturing NAD+ raw materials isn’t just making a molecule — it’s protecting it from the world until it reaches yours.

4. The Qualities That Define a Trusted NAD+ Raw Material Manufacturer

So how do you tell the difference between a mediocre supplier and a world-class NAD+ raw material manufacturer?

Let’s break down the defining traits that separate the leaders from the laggards.

1. Purity, Consistency, and Analytical Testing

The foundation of any NAD+ product is its purity. For a supplement brand, a few percentage points can make or break product effectiveness. The top manufacturers routinely achieve:

≥ 99% purity levels, verified by HPLC and LC-MS

Batch-to-batch consistency testing

Microbial and endotoxin control

Absence of heavy metals (As, Pb, Hg, Cd)

These aren’t just buzzwords. They’re proof points supplement brands can display confidently in their marketing — “pharmaceutical-grade NAD+ purity” carries weight with both consumers and regulators.

2. Sustainability and Green Chemistry

In 2025, sustainability isn’t optional — it’s a competitive advantage. Leading NAD+ raw material manufacturers have embraced green chemistry principles, such as:

Using biological fermentation instead of petrochemical synthesis

Recycling water and solvents in production

Minimizing CO₂ emissions via energy-efficient bioreactors

Implementing waste valorization — turning byproducts into reusable materials

Compared to older synthetic methods, these eco-friendly processes are cleaner, safer, and more sustainable — a key selling point for modern, eco-conscious supplement brands.

3. Global Certifications and Traceability

A manufacturer’s certifications are like their passport to global credibility. The most trusted NAD+ suppliers proudly hold:

| Certification | Description | Why It Matters |

| GMP (Good Manufacturing Practice) | International standard ensuring production quality and safety | Guarantees pharmaceutical-level quality |

| ISO 9001 / ISO 22000 | Quality and food safety management systems | Demonstrates rigorous process control |

| FDA Registered Facility | Approval for operations in the U.S. market | Required for compliance and trust |

| Halal / Kosher Certification | Religious and ethical production validation | Expands global market access |

| Non-GMO, Vegan, Gluten-Free | Label-friendly attributes | Meets modern consumer preferences |

Manufacturers with these credentials demonstrate traceability from raw material sourcing to final product packaging, allowing partners to audit their supply chains confidently.

4. Innovation and R&D Capabilities

In a fast-evolving market, the best manufacturers don’t just produce — they innovate. Through partnerships with biotech labs and universities, they continually explore new synthesis routes, stability enhancers, and delivery formats.

For example:

Developing microencapsulated NMN for better stability in heat and humidity.

Using AI-assisted strain engineering to increase fermentation yield.

Designing sustained-release NAD+ formulations for clinical applications.

A manufacturer that invests in R&D today becomes your innovation partner tomorrow.

5. Customer-Centric Approach

Finally, it’s not just about molecules — it’s about relationships. Top-tier NAD+ manufacturers offer:

Custom formulation support

Flexible MOQs (Minimum Order Quantities)

Fast lead times and stable supply

Regulatory documentation for global compliance

White-label or private-label production services

This client-first mindset transforms them from a supplier into a strategic partner, enabling supplement brands to scale faster, innovate confidently, and maintain consistent quality across product lines.

Summary: What Sets the Best NAD+ Manufacturers Apart

| Key Factor | Top-Tier Manufacturer | Average Supplier |

| Purity | 99%+ verified via HPLC | 90–95%, often unverified |

| Technology | Enzymatic / fermentation-based | Chemical synthesis |

| Certifications | GMP, ISO, FDA, Halal/Kosher | Limited or missing |

| Traceability | Full batch traceability | Partial records |

| Sustainability | Green chemistry processes | Traditional chemistry |

| Partnership Value | Customization, R&D collaboration | Basic supply service |

When supplement brands evaluate suppliers, these criteria act like a checklist for trust and performance. Choosing a manufacturer that aligns with these standards ensures not just superior product quality, but also a stronger, more credible brand in the eyes of consumers and regulators alike.

5. Market Outlook: The Expanding Global NAD+ Industry

If there’s one phrase that captures the NAD+ industry today, it’s this: the perfect storm of science, demand, and innovation. Once a niche topic in academic journals, NAD+ has become the molecular celebrity of the wellness world — attracting attention from biohackers, nutritionists, pharmaceutical companies, and longevity researchers alike.

But what’s truly fascinating is not just the hype — it’s the numbers behind it.

Explosive Growth of the Global NAD+ Market

The global NAD+ industry is currently on a double-digit growth trajectory. According to several market research reports published between 2024–2025, the combined market size for NAD+, NMN, and NR raw materials is projected to surpass USD 1.5 billion by 2030, growing at a CAGR of 25–30%.

So, what’s driving this exponential rise?

Aging population – As life expectancy increases globally, more consumers are investing in longevity-focused nutrition.

Scientific validation – Dozens of studies show that restoring NAD+ levels can improve metabolism, mitochondrial function, and DNA repair.

Consumer awareness – Influencers, wellness brands, and biohacking communities have brought NAD+ into mainstream conversation.

Product diversification – NAD+ precursors aren’t just in supplements anymore — they’re appearing in energy drinks, skincare serums, injectables, and even pet nutrition.

Compared to five years ago, NAD+ has gone from “science fiction” to a core ingredient in global wellness and anti-aging portfolios.

Key Regional Markets: Who’s Leading the Charge?

| Region | Market Characteristics | Growth Outlook |

| North America (U.S., Canada) | Strong consumer awareness; home to leading supplement brands; high R&D investment | Fast-growing; expected CAGR >25% |

| East Asia (China, Japan, South Korea) | Major raw material manufacturing hub; rapid industrial scaling | Very strong; global production leader |

| Europe | Increasing regulatory standardization; luxury skincare integration | Moderate but steady growth |

| Southeast Asia & Australia | Emerging market for imported NMN products | Growing consumer adoption |

China and Japan are currently the world’s largest producers of NAD+ precursors, while the United States remains the biggest consumer market. Western brands are now partnering with Asian biotech manufacturers to secure reliable, high-purity NMN and NAD+ supplies.

Applications Beyond Supplements

It’s easy to think of NAD+ only in capsule form, but its applications are expanding at lightning speed.

Nutritional Supplements: Capsules, sublingual tablets, and drink powders for energy and longevity support.

Skincare and Cosmetics: NAD+ and NMN are being added to anti-aging creams for DNA repair and mitochondrial rejuvenation.

Pharmaceuticals: NAD+ boosters are under investigation for neurodegenerative diseases, metabolic disorders, and age-related decline.

Sports Nutrition: Athletes are turning to NAD+ products to enhance endurance and muscle recovery.

Each of these segments represents a lucrative vertical for raw material manufacturers, especially those offering customized grades or enhanced-stability formulations tailored to specific industries.

Shift from Synthetic to Bio-Fermented NAD+ Raw Materials

The industry is undergoing a clear transition — from synthetic chemistry to bio-fermented NAD+ raw materials. Why? Because fermentation not only produces cleaner, safer, and more sustainable compounds but also resonates with eco-conscious consumers.

Here’s the comparison at a glance:

| Aspect | Synthetic NAD+ | Bio-Fermented NAD+ |

| Production Method | Chemical synthesis using solvents | Fermentation using yeast or bacteria |

| Purity | 95–97% | ≥99% |

| Environmental Impact | Higher waste and emissions | Minimal waste, greener |

| Cost | Slightly cheaper per batch | More expensive but scalable |

| Consumer Perception | “Artificial” or lab-made | “Natural,” “bio-based,” clean-label |

The trend mirrors what happened in the vitamin C and collagen industries — bio-fermented forms gradually replaced synthetics due to better marketing appeal and consumer trust.

For NAD+, this shift also means manufacturers must invest in fermentation technology, strain engineering, and downstream purification, which are more capital-intensive but yield long-term advantages.

Collaboration Between Biotech Companies and Supplement Brands

One of the most exciting developments in the NAD+ market is the strategic collaboration between biotech firms (which specialize in R&D and fermentation) and consumer supplement brands (which focus on marketing and retail).

This synergy brings together:

Scientific credibility from biotech labs

Consumer access through established supplement brands

Supply stability through joint manufacturing agreements

For example, many NAD+ raw material manufacturers now offer co-branding opportunities, allowing supplement companies to highlight “powered by biotech” or “pharma-grade NMN” on their labels — a win-win for both parties.

The NAD+ Market Outlook: What’s Next

Over the next five years, expect to see:

A rise in AI-driven production optimization, increasing fermentation efficiency.

Regulatory clarity in major markets like the U.S. and EU, improving consumer trust.

Expansion into personalized nutrition, where NAD+ supplements are tailored based on genetic testing and biological age.

Wider adoption in medical-grade NAD+ therapies, such as intravenous infusions and NAD+-based drug delivery systems.

In short, the NAD+ market isn’t just expanding — it’s maturing, moving from hype to high-tech.

6. Choosing the Right NAD+ Raw Material Partner

Now that we’ve explored the science and the market, let’s get practical. If you’re a supplement brand, nutraceutical startup, or research company, how do you choose the right NAD+ raw material manufacturer?

The right partnership can define your product’s success — or failure. Let’s walk through a checklist that separates the professionals from the pretenders.

1. Quality Assurance Above All

When it comes to NAD+ or NMN, quality isn’t negotiable. You’re dealing with a molecule that’s unstable, sensitive, and potency-dependent. So your manufacturer must guarantee:

High assay purity (≥99%)

Low moisture (<1%) for shelf stability

Absence of residual solvents, microbes, and heavy metals

Batch-to-batch uniformity verified by third-party labs

If your supplier can’t provide a full Certificate of Analysis (CoA) and third-party testing documentation, it’s a red flag.

Compared to standard supplement ingredients like vitamin B3 or CoQ10, NAD+ compounds require stricter control due to their delicate structure and rapid oxidation potential.

2. Transparent Sourcing and Manufacturing Practices

Transparency is more than a buzzword — it’s your legal and ethical safety net.

A reliable manufacturer should provide:

Detailed sourcing traceability for every raw input

Batch production records available for audit

Disclosure of production site location and GMP status

Leading NAD+ raw material suppliers even implement blockchain-based tracking, ensuring every gram of NAD+ powder can be traced from fermentation vat to your factory door.

That’s how you build long-term trust — both with regulators and customers.

3. Third-Party Testing and Verification

A manufacturer’s own testing is good. Independent testing? Even better.

Partner with manufacturers that collaborate with accredited third-party labs (such as SGS, Eurofins, or NSF International). These external reports validate purity claims, safety parameters, and labeling accuracy — critical for compliance in markets like the U.S. (FDA) or Europe (EFSA).

It’s a bit like getting an unbiased referee in a game — you know the score is fair.

4. Scalability and Customization

Your supplier should be able to grow with you. Look for a manufacturer that offers:

Scalable capacity — from small R&D batches to metric tons

Customized particle size or purity grades for different applications (capsules vs. liquids vs. cosmetics)

Formulation-ready options, such as microencapsulated or buffered NMN powders

This flexibility ensures your product line can expand without changing suppliers — saving time, money, and regulatory headaches.

5. Regulatory Support and Documentation

A strong NAD+ manufacturer acts as your compliance partner. They should provide:

MSDS (Material Safety Data Sheets)

Stability and safety studies

Product specifications and technical dossiers

Support during regulatory submissions

This is crucial if you’re selling in multiple markets, where NAD+ regulations may differ. For example, Japan treats NMN as a “functional food,” while the EU may classify it as a “novel ingredient.” Having a manufacturer that understands these nuances is invaluable.

6. Long-Term Partnership Value

The best NAD+ supplier relationships go beyond transactions — they’re collaborations built on innovation and mutual growth.

A great manufacturer doesn’t just supply powder; they help you:

Co-develop new NAD+ delivery systems (like liposomal or sustained-release formulas)

Participate in joint clinical trials or pilot studies

Launch co-branded product lines highlighting their proprietary manufacturing process

This kind of partnership creates a competitive moat — your brand benefits from exclusive formulations and credibility backed by cutting-edge biotech.

Quick NAD+ Manufacturer Checklist

| Evaluation Criteria | What to Look For | Why It Matters |

| Purity & Testing | ≥99% purity, HPLC & MS verification | Ensures product efficacy |

| Certifications | GMP, ISO, FDA, Halal/Kosher | Guarantees compliance |

| Transparency | Full traceability reports | Builds brand trust |

| Scalability | Ability to meet growing demand | Supports business expansion |

| Innovation | Fermentation, AI optimization, microencapsulation | Keeps your brand ahead |

| Support | Regulatory and documentation help | Simplifies compliance |

By following this checklist, supplement brands can confidently evaluate potential partners, avoid low-quality suppliers, and build sustainable relationships that grow with market demand.

7. The Future: NAD+ Innovation and Beyond

The NAD+ industry isn’t slowing down — it’s evolving. What began as a biochemical curiosity is transforming into one of the most dynamic sectors in modern biotechnology. The next decade will see NAD+ go from a single superstar molecule to a platform for longevity innovation — where chemistry, AI, sustainability, and personalized health converge.

Let’s peek into what’s next for NAD+ raw material manufacturing and why it matters for B2B supplement brands, researchers, and biotech investors alike.

1. The Evolution Toward NAD+ Analogs and Synergistic Compounds

Science never stands still. While NAD+, NMN, and NR are well-established, researchers are already developing NAD+ analogs — modified molecules that deliver even stronger, longer-lasting cellular benefits.

For example:

NADH (reduced NAD+) offers faster energy release and is ideal for sports recovery.

NADP+ (phosphorylated NAD+ form) shows potential in metabolic regulation and antioxidant protection.

Novel analogs like Acetyl-NMN or stabilized NAD+ esters are being studied for better bioavailability and resistance to oxidation.

Compared to traditional NAD+, these analogs could be more stable, more potent, and more targeted, especially in pharmaceutical or therapeutic applications. Expect raw material manufacturers to expand their R&D pipelines accordingly — offering differentiated product portfolios that help brands stand out.

2. Integration of AI-Driven Biotech R&D

Artificial Intelligence is quietly revolutionizing biotech manufacturing — and NAD+ production is no exception.

AI algorithms are now used to:

Optimize fermentation parameters in real time, improving yield by up to 30%.

Predict enzyme performance and identify more efficient biosynthetic pathways.

Model stability and shelf life of NAD+ powders under different storage conditions.

Imagine having an AI “lab assistant” that runs 10,000 simulations overnight, predicting which microbial strain will produce NAD+ faster and cleaner. This isn’t science fiction — it’s already happening in next-gen biotech labs across Asia and North America.

Manufacturers embracing AI-assisted production will gain massive advantages: faster innovation cycles, lower costs, and superior consistency compared to traditional trial-and-error methods.

3. Sustainability and Ethical Sourcing in Future Production Models

The future of NAD+ isn’t just about performance — it’s about planet-friendly production.

Biotech manufacturers are under growing pressure to reduce their environmental footprint. The most forward-thinking NAD+ suppliers are adopting:

Zero-waste fermentation systems

Closed-loop water recycling

Solar-powered bioreactors

Ethical sourcing of feedstocks (e.g., plant-based carbon sources instead of petrochemicals)

Compared to older industrial setups, these models are greener, lighter, and more efficient. And beyond the obvious environmental benefits, they also enhance brand reputation — especially for supplement companies promoting “clean label” and “eco-conscious” wellness products.

4. Regulatory Harmonization and Market Transparency

Right now, the NAD+ industry operates in a patchwork of global regulations. For example:

In the U.S., NMN is under ongoing FDA review as a dietary ingredient.

In Japan, NMN is classified as a functional food ingredient.

In the EU, NMN and NAD+ are treated as “novel foods,” requiring pre-market authorization.

Over the next few years, expect clearer, unified frameworks that will legitimize NAD+ across markets. That will unlock opportunities for international product launches and standardize purity, labeling, and dosage requirements.

Manufacturers that prepare early — by maintaining full documentation, safety studies, and transparent traceability — will have a significant first-mover advantage when these regulations settle.

5. Personalized NAD+ Supplementation: The Next Frontier

Imagine this: a simple at-home blood test or wearable device tells you your NAD+ levels, then an app recommends a personalized daily dose of NMN or NADH — delivered in a formulation optimized for your genetics, lifestyle, and biological age.

That’s not far off. Companies are already merging nutrigenomics (nutrition + genetics) with AI-powered health platforms to deliver personalized NAD+ optimization plans.

This evolution will create an entirely new business model — not just selling NAD+ as a product, but as a data-driven health service. And the raw material manufacturers behind it? They’ll become the biotech backbone of personalized longevity.

6. Collaboration is the Future

In the coming years, the NAD+ ecosystem will look less like a competitive battlefield and more like a collaborative network — with manufacturers, biotech labs, and brands co-developing innovations that push the frontier of human health.

Partnerships will focus on:

Joint clinical trials proving efficacy

Technology transfer between biotech startups and supplement giants

Sustainability alliances to create greener production chains

The winners won’t just be the biggest manufacturers — but those that collaborate the best.

To wrap things up, here’s a detailed, SEO-optimized FAQ section covering the most common questions asked by buyers, supplement brands, and researchers about NAD+ raw material manufacturing.

| Question | Answer |

| 1. What is NAD+ and why is it important? | NAD+ (Nicotinamide Adenine Dinucleotide) is a coenzyme essential for energy metabolism, DNA repair, and cellular communication. It declines with age, leading to fatigue, aging, and metabolic dysfunction. |

| 2. What are NAD+ precursors? | NAD+ precursors such as NMN, NR, and NAM are compounds that the body converts into NAD+. They’re used in supplements because they’re more bioavailable than direct NAD+ intake. |

| 3. How are NAD+ raw materials manufactured? | Typically through fermentation-based biosynthesis, followed by purification (HPLC, filtration, crystallization), drying, and GMP-quality testing. This ensures high purity and safety. |

| 4. Why choose bio-fermented NAD+ instead of synthetic? | Bio-fermented NAD+ is cleaner, greener, and has fewer contaminants. Although slightly more expensive, it’s more sustainable and consumer-friendly. |

| 5. What certifications should a reliable NAD+ manufacturer have? | Look for GMP, ISO 9001/22000, FDA registration, Halal, and Kosher certifications. These prove compliance and quality standards. |

| 6. How can supplement brands ensure NAD+ product stability? | Store NAD+ or NMN powders in cool, dry conditions, using nitrogen-sealed or vacuum-packed containers. Some manufacturers offer microencapsulated versions for longer shelf life. |